| A transformer is an electrical device that transfers energy between two or more circuits through electromagnetic induction. A varying current in the transformer’s primary winding creates a varying magnetic flux in the core and a varying magnetic field impinging on the secondary winding. This varying magnetic field at the secondary induces a varying electromotive force (emf) or voltage in the secondary winding. Making use of Faraday’s Law in conjunction with high magnetic permeability core properties, transformers can thus be designed to efficiently change AC voltages from one voltage level to another within power networks. A wide range of transformer designs is encountered in electronic and electric power applications. Since the invention in 1885 of the first constant potential transformer, transformers have become essential for the AC transmission, distribution, and utilization of electrical energy. As consistent guarantee of the highest quality Distribution Transformers are manufactured from CRGO (cold rolled grain oriented) silicon steel. Quality control is carried out at all stages of production while final routine and type tests are performed in our well equipped testing laboratory according to IEC-76, BDS 1081, ANSI, AEC and BSTI standards. |

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

STANDARDS & DESIGN |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

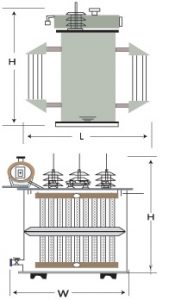

| TRANSFORMER’S PHYSICAL DIMENSIONS | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

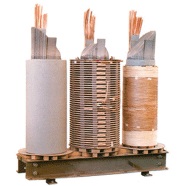

| CORE, COIL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

The core is built with laminations of high grade grain-oriented silicon steel. The special cutting and stacking methods result in low no load losses and low noise levels. Wound on mandrel, the core is annealed at the highest temperature to relieve mechanical stress and fix into the design shape. Low cold rolled grain oriented silicon steel strip. The core is built with laminations of voltage coils are normally larger layer wounds using paper insulated copper conductor. Circular type and rectangular type windings are respectively used for relatively large or small type of transformers. The coil has to allow the liquid insulation for cooling. It causes uniform heat dissipation due to losses. The round conductor windings consist of individually wound coil sections connected in series to produce phase winding. We use high grade Imported copper for winding and export quality super enamel wires for HT windings. HT and LT coils are checked for inner diameter, outer diameter, axial length, number of turns and resistance. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| INSULATION | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| The dielectric circuit of transformer which isolates the magnetic & electric circuit & their parts, insulation papers and press board of high quality are used for our Transformer. Moisture content of the insulation paper is very minimum. Drying system removes almost all moisture from the insulation structure and finally from the transformer. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| BUSHING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| High voltage and low voltage bushing are of wet process porcelain terminals suitable for copper or aluminum conductors. All the bushings are top mounted. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TRANSFORMER OIL | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Transformer oil is procured from reputed manufacturers. It is tested for resistivity dielectric dissipation factor, acidity, flash point, pour point, break down voltage and inter facial tension as per BIS & IEC. No further drying will be required before putting into operation.

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Tap changer is made of high quality homogeneous insulating board or synthetic resin mold is mounted below oil level for changing the connections of taps in primary windings. In almost all our distribution transformers, we use imported tap changer from reputed Company. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

Conservator Tank is detachable by providing a flange at its point of RADIATORS connection to the tank cover. Transformer tank is made with steel sheet and covers are fabricated by welding. Tank is tested under pressure for finding any leakage. Tanks employed for housing the core coil assembly are mechanically strong. Tank finish consists of three coats. Each coat is applied uniformly and cured at even temperature. For properly making of radiator is very important. Each individual element and radiator under assembled condition is tested with air pressure of approximately 3kg/cm2. Tank painted by a zinc riched primer coat and two finishing coats as required by the customer. Powder coated radiator is also available on request. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ACCESSORIES | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| – HT/LT Bushing with terminal connectors – Oil level Indicator- Oil drain plug – Buchholz relay- Gate valve – Tap changers – Lifting-Lug – Thermometer (for 3 phase transformer) – Name plate with connection diagram – Silica gel breather for the conservator tank – Pressed steel radiator- Earthing terminal |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SPARE ACCESSORIES ON REQUEST | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| – Flexible connector from LV Bushing to BBT end connection unit. – High voltage plug in connectors. – Marshalling box with accessories for thermal protection. – Temperature measurement by means of a PT100 resistor in the middle phase, with digital or analog indicator with or without contacts. – Digital display of temperature on the 3 phases with contacts and storage of maximum values. – Fans with control and control box for forced cooling (increases the rating with 10%) – WTI, OTI, Buchholz Relay – Vibration dampers. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| TESTING | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Routine Test | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| * Insulation resistance test * Core insulation test * Winding resistance test * Voltage ratio & polarity test (vector group test) * No load loss & exciting current measurement test * Load loss & impedance voltage measurement test * Dielectric strength test of oil * Power frequency (separate source) voltage withstand test * Short-circuit test* Function of tap changer test * Heat-run test at ONAN and ONAF rating (specify) |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Test certificates are issued for all the above tests on request | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Type Test * Impulse voltage withstand test * Temperature rise test * Oil leakage test * Over load test * Noise level test |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| WARRANTY | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| HAMMER TECH committed to its valued client for trouble free operation of our supplied equipment and under make warranty for free replacement of any part or parts failing due to manufacturing defect, which shall not include normal operational wear and tear for a period of 36 Months from the date of delivery. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| SERVICE | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Repairing of power transformer are also taken care of in our factory or at site of installation. Rectifier and AC/DC welding transformer are also be repaired on request. Retrofitting in feeder unit and out feeders with any kind of circuit breakers, including re-winding & repair of transformer, fittings. For repairing of winding & up to 33 kV assembly and OLTC utility and big substation owners can contact us in full confidence. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||